Ceramic

Created November 12, 2007

Different types of clays, inclusions, and manufacturing techniques lead to different effects among distinct pottery types. Since all pottery—historic and prehistoric—has been fired to some degree, heat damage is not as significant a consideration for this artifact type as it is for others. Generally, structural damage does not occur until temperatures exceed the original firing temperature. The main type of damage noted is to the surface decoration or glaze.

Prehistoric Ceramics

Temperatures do not exceed the original firing temperature for most prehistoric ceramics until about 600 C (1112 F) (Andrews 2004).

At the time of manufacture, most prehistoric pottery was fired at temperatures in the 400-600°C range (Cogswell et al. 1997; Colten 1951; Feathers et al. 1998; Goodyear 1971; Heimann and Franklin 1979; Kaiser and Lucius 1989; Rice 1987; Roberts 1963; Rye 1981; Shepard 1956; Tite 1969; Ziad and Roussan 1999). Under prescribed and wildland fire conditions, prehistoric ceramic materials should remain relatively stable until temperatures climb beyond original firing temperature and/or the temperature gradient becomes excessive and induces significant thermal stress. (Buenger 2002)

Fire can, however, affect the appearance of pottery shards, possibly leading to mis-identification. Effects from fire include surface spalling, alteration of painted decoration, blackening and sooting, and loss of appliqué designs which may break off. In one experiment painted designs faded and turned color at temperatures greater than 800 C (1472 F). However, sooting or blackening may be removed by cleaning in a lab, and discoloration does not necessarily prevent identification of pottery type (Rude n.d.).

Fire may affect the potential for thermoluminescence (TL) dating. However, surface potsherds are generally not used for this technique, and buried potsherds are not likely to be affected by fire. Another study also showed that TL dating was not affected at temperatures below 400 C (752 F), indicating that moderate intensity wildland and prescribed fire may not have an impact on TL dating (Rude n.d.).

Historic Ceramics

Historic ceramics consist of earthenwares, stonewares, and porcelain. These types of pottery are differentiated in part by the heat of firing. All of these pottery types may be glazed, and the glaze or other decoration is likely to be the most vulnerable characteristic. Some early glazes (e.g. majolica glaze) and glazes on “whiteware” (refined earthenware common at nineteenth and twentieth century sites) may crackle or spall even in a low temperature fire.

Historic ceramic materials such as porcelain and china are fired at temperatures of 1280-1400°C, and beyond (Rice 1987). However, these materials are manufactured to withstand significant thermal stress due to quality controlled manufacture and high firing temperature. (Buenger 2002)

Thermal Alteration of Ceramics

In general, thermal fracture of pottery occurs as the result of tensile or compressive stress generated by thermal gradient that exceeds the strength of the ceramic body. Important variables affecting this process include the coefficient of thermal expansion, thermal conductivity, temperature differential, and temperature gradient (Hasselman 1970; Kingery 1955; Rice 1987). In addition, Schiffer et al. (1994) have reported that thermal spalling occurs were steam pressure produces sufficient stress to exfoliate elliptical portions of ceramic surfaces, particularly where irregularities in the surface are present.

observable alterations (from Burgh 1960; Lentz et al. 1996; Switzer 1974)

-

thermal fracture,

thermal fracture, -

thermal spalling,

thermal spalling, -

combustion of organic paint, and

combustion of organic paint, and -

oxidation or re-firing resulting in subsequent color alteration .

oxidation or re-firing resulting in subsequent color alteration .

Oppelt and Oliverius (1993) have demonstrated that the application of fire retardant foam during burning will induce thermal shock among Mesa Verde Pottery sherds. The experiment did not document the potential for thermal fracture or spalling of sherds during combustion of natural fuels alone.

Prehistoric Ceramics:

> 350°C (662 F) - Minor effects (sooting, fading, discoloration)

> 400°C (752 F) - TL dating potential compromised

> 500°C (932 F) - redware varieties can change to a darker hue,

black-on-white wares will change to a “slightly buff” color

(based on laboratory experimentation using a muffle furnace, Bennett and Kunzmann (1985)).

> 600°C (1112 F) - Structural change possible

black-on-white sherds can oxidize to resemble redware (Under laboratory conditions)(Burgh 1950; Colten 1953; Shepard 1956). Bennett and Kunzmann (1985) also suggest that the pigmented design on black-on-white sherds is stable under high temperature if the paint is mineral based, but may combust and fade significantly if the paint is organic based.

Theoretically, thermoluminescence (TL) signal of sherds burned during wildland fires may be altered depending on temperature, rate and duration of heating experienced by the specimen during the fire. TL dating is generally not affected by heating where the temperature is less than 250°C (Aitken 1985). Rowlett (1991) and Rowlett and Johannessen (1990) demonstrated that wildland fire at Bandelier National Monument, New Mexico changed the TL reaction for pottery sherds. Two specimens from surface contexts exhibited age underestimations of 24%. Although the scope of this project was limited, it illustrates that potential for wildland fire to negatively impact the validity of use TL techniques to date sherd from surface contexts where wildland fires have occurring in the recent or distant past.

Historic Ceramics:

500–900°C (932–1652 F) - Unrefined Earthenware - Glazes may crackle and spall at low fire temperatures

900–1100°C (1652-2012 F) - Stoneware - Temperatures above firing point may oxidize glaze or crack shards

1100–1500°C (2012-2732 F) - Refined Earthenware (“whiteware”) - Glaze may crackle at low fire temperatures

1250-1450°C (2282-2642 F) - Porcelain - Temperatures above firing may oxidize glaze or crack shards

References

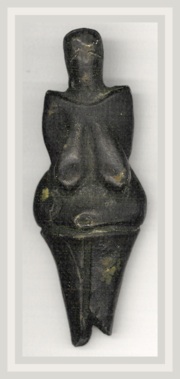

Earliest known ceramics are the Gravettian figurines that date to 29,000 to 25,000 B.C. (http://en.wikipedia.org/wiki/Pottery)

Burgh, R. F., 1960. Potsherds and Forest Fires in the Pueblo Country. Plateau 33, 54-65.

Colton, H. S., 1951. Hopi Pottery Firing Temperatures. Plateau 24, 73-76.

Hasselman, D. P. H., 1970. Thermal Stress Resistance Parameters for Brittle Refractory Ceramics. American Ceramic Society Bulletin 49, 1033-1037.

Johnson, J. S., Clark, J., Miller-Antonio, S., Robins, D., Schiffer, M. B., and Skibo, J. M., 1988. Effects of Firing Temperature on the Fate of Naturally Occurring Organic Matter in Clays. Journal of Archaeological Science 15, 403-414.

Rowlett, R. M., 1991. Ancient grass fires detected by thermoluminescence. Archaeology in Montana 32, 29-32.

Rowlett, R. M., 1991. Ceramic thermoluminescence response effects after the La Mesa Forest fire, Bandelier National Monument. Archaeology in Montana 32, 49-56.

Rowlett, R. M., and Johannessen, S., 1990. Appendix G. Thermoluminescence response interference from the La Mesa forest fire, Bandelier National Monument. In: Traylor, D., Hubbel, L., Wood, N., and Fiedler, B., (Eds.), The 1977 La Mesa Fire Study: An investigation of fire and fire suppression impact on cultural resources in Bandelier National Monument. National Park Service, Division of Anthropology, Branch of Cultural Resources Management, Santa Fe, pp. 178-188.

Shepard, A. O., 1939. Appendix A: Technology of La Plata pottery. In: Morris, E. H., (Ed., Archaeological studies in the La Plata District, Southwest Colorado and Northwest New Mexico. Carnegie Institute of Washington, Washington, D.C., pp. 249-288.

Shepard, A. O., 1956. Ceramics for the archaeologist. Carnegie Institution of Washington, Washington, D.C.

Overview

Constructed with much sweat by Linn Gassaway.

Remember conditions are not static so Not making a decision is a decision.

Be safe No archaeological site is worth a life.

This page is still under construction so please check back for additional information.

Website last updated October 26, 2011